RWE aims to expand the remote control of power stations and plants for renewables step by step. It has a range of pilot projects in progress to define schedules for operating smaller plants from central control rooms, for example. Efficient analytical and visualisation tools operate together in a dashboard prototype that displays operational data in real time. Power engineers, data specialists and IT developers are working to achieve the best possible solutions. Many power generation plants at RWE are already capable of being operated by remote.

In volatile markets, flexible plants offer major potential. And the new digital platform D-Central enables RWE Supply & Trading to make the best possible use of these potentials. The platform provides a highly scalable IT infrastructure based on a virtual power plant. It bundles decentralised, flexible plants to form a virtual pool and makes them available to the electricity markets. That enables the plant operators to benefit from the expertise of the trading company in the area of asset optimisation, and from state-of-the-art algorithms. The high level of automation offered by the platform is a key deciding factor in being able to manage the many different types of plant and the various market demands. That means that controllable power, which has not previously been offered, can be optimally marketed on short-term markets or as operating reserve. And of course the energy system as a whole benefits. Electricity generation, which depends increasingly on sun and wind, is brought into better balance with demand. It’s a classic win-win situation.

The task for RWE Offshore Wind is to industrialise its operations to ensure it is prepared for the ambitious goal of reaching a network capacity of 8 GW by 2030. One of the most important initiatives here is the development of a joint portfolio process that is continuously improved and is based on the proven methods in use at the existing RWE wind farms. This process will serve as a model for future locations and will help the company to work more efficiently and effectively.

A digital ecosystem is therefore currently being developed to comprehensively control processes and increase their efficiency. Wherever possible, the digital ecosystem solutions are developed with a focus on the user, in order to make the best possible use of the many years of experience accrued by the company.

The digital ecosystem comprises several solutions that communicate with each other. It enables users to enter information just once, to allow the data to flow seamlessly between the applications with a high level of automation.

Please click on the image to zoom

Please click on the image to zoom

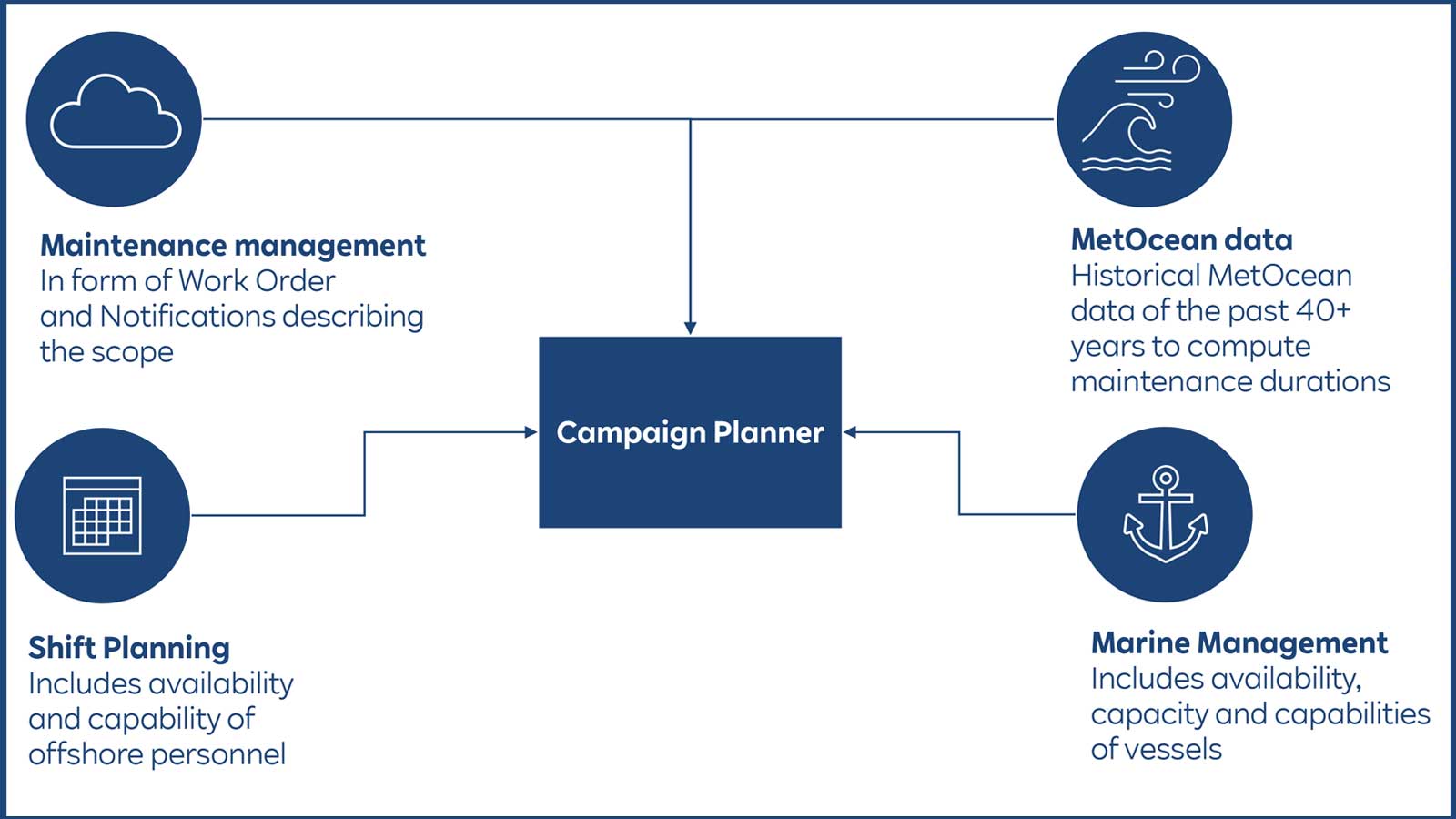

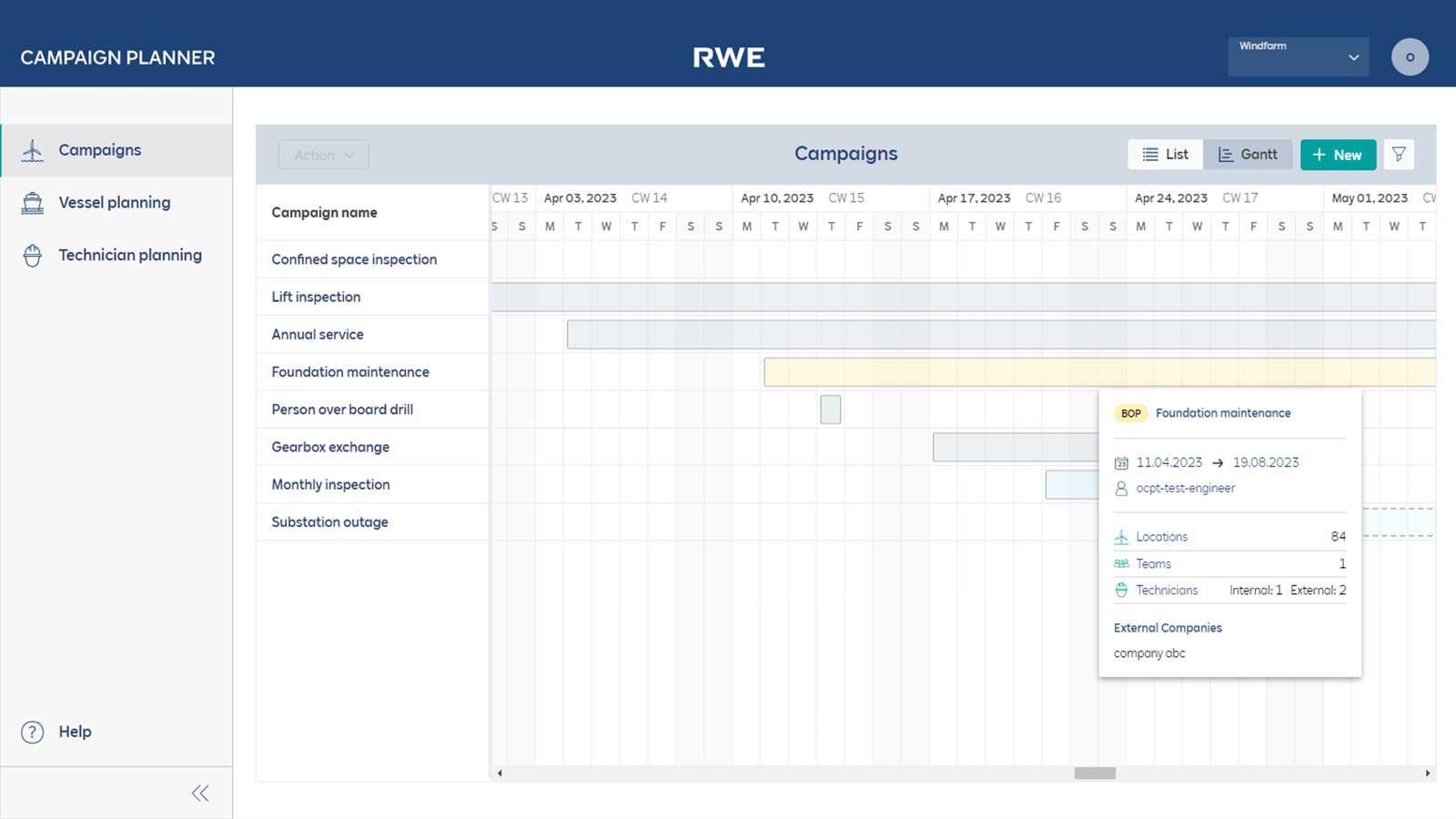

The Campaign Planner is one of the core applications in the digital ecosystem. It includes the long-term maintenance planning process by bringing together the necessary data, such as ship availability, engineer availability, maintenance information and historical MetOcean data within a single system. That enables RWE Offshore Wind to plan and optimise its maintenance activities quickly and cost-efficiently.

A robot dog called “Power Pup” is currently being tested at the Claus C gas-fired power station in the Netherlands in order to ease the burden of day-to-day tasks on the employees on-site. Power Pup is innovative and equipped with advanced sensors and cameras that enable it to find its way in complex environments and perform tasks that leave more time for the employees on-site to devote to other activities. Following a successful safety introduction, the robot dog will autonomously perform tasks such as inspection and checking rounds in future. Thanks to its many different sensors, the robot can detect problems at an early stage, and it is also equipped with all kinds of instruments that enable it to perform the inspections.